An innovation becomes the “MAPAL reamer”

THE TRIUMPHAL PROCEEDINGS OF AN INVENTION DISDAINED IN THE BEGINNING

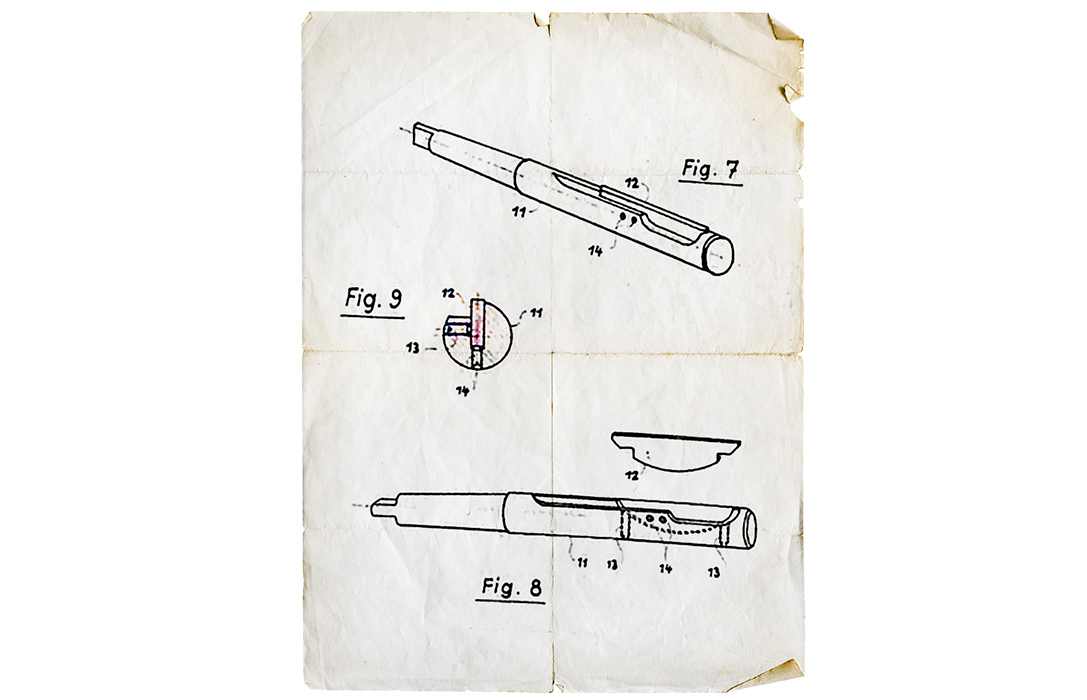

In 1952, the Italian engineer Melchiore from Milan travelled to Germany to sell the patent for an invention he had made: A single-bladed reamer that is not equipped with four or six blades, as was previously the case, but with just one that can be adjustably clamped in a slot. The principle promises lower manufacturing costs, higher speeds and feed rates as well as greater flexibility. The inventor approached around twenty German tool manufacturers - without success. They all doubted that his design would work in practice. When Melchiore finally offers his patent to MAPAL, the experts there are equally dismissive. Only a non-technician could invest money in the dubious invention.

Dr Georg Kress is one such person. Against the advice of his technicians, he acquires the patent for the single-edge reamer for 20,000 German Marks. He soon realised that the design actually had numerous weak points and did not work as hoped. Instead of giving up, the founder now establishes a principle that will shape his company: optimisation through intensive, meticulous and tenacious series of tests. Two axially asymmetrically arranged, strip-shaped guides represent a breakthrough.

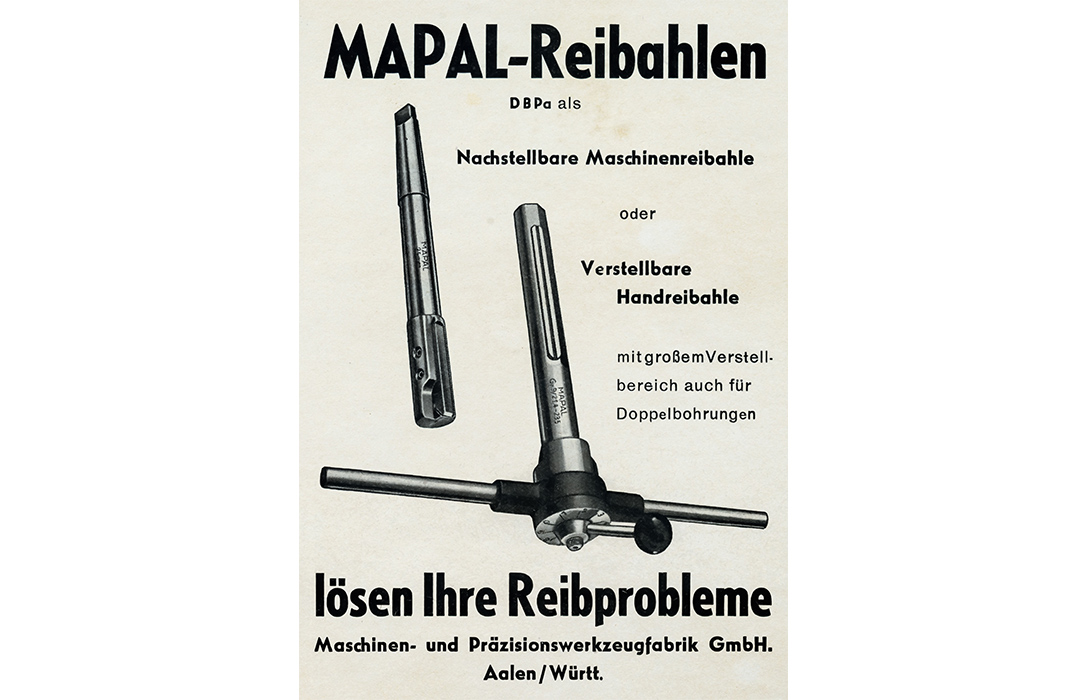

In 1954, the single-bladed reamer is launched on the market, accompanied by intensive advertising campaigns. Thanks to its negative cutting angle, a wide range of materials can be machined with a long tool life, and the innovation from Aalen quickly becomes a sought-after product. In the following years, numerous developments such as indexable inserts and guide pads made of carbide, coated indexable inserts and guide pads made of polycrystalline diamond (PCD) improve and expand the application possibilities of the “MAPAL reamer”.

This made it possible to machine forged steel in large-scale production in the 1970s. The once ridiculed patent now not only convinces renowned customers from the automotive industry, but also becomes a unique success factor for MAPAL.