MAPAL is on course for success with specialisation

1970–1989

Initiated by Dr Dieter Kress, MAPAL is making far-reaching changes to its corporate strategy: the company is focusing entirely on single-bladed reamers. These are being technically optimised and made usable for further applications. A new, customer- and advice-oriented sales concept is also helping to attract numerous customers from large-scale production.

In 1974, Dr Dieter Kress took over the management of the company from his father. In contrast to his father, he is a passionate engineer and holds a doctorate in mechanical engineering. Even as a student, he was intensively involved in optimising single-bladed reamers. In 1975, he pushed through a decision to focus entirely on this product range because, unlike with ‘off-the-shelf’ products such as thread cutting tools, MAPAL can clearly differentiate itself from its competitors with its expertise in this area.

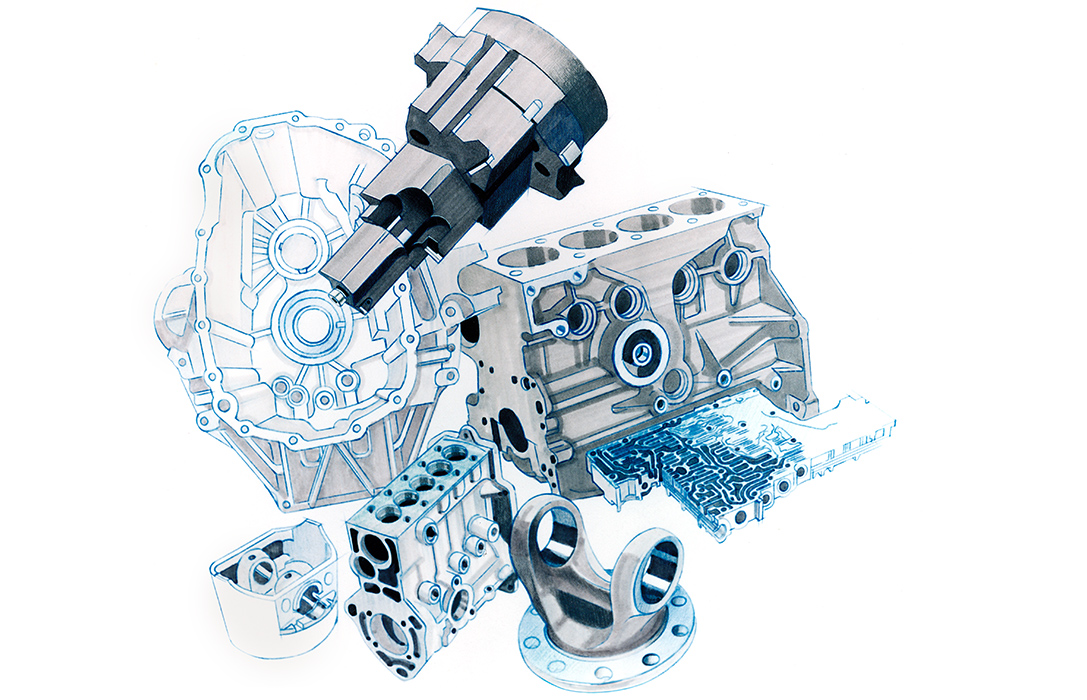

The reorientation includes further improvements to the reamers, such as CVD coatings (Chemical Vapour Deposition) for the carbide indexable inserts or guide pads made of PCD (Polycrystalline Diamond). MAPAL's fine machining tools are therefore also suitable for machining forged steel and, due to the improved tool life, are increasingly being used in the flexible machining centres of large-scale production, particularly in engine and gearbox machining in the automotive industry.

In parallel with the technical optimisations, Dr Dieter Kress is changing the sales structures. The previous system of freelance sales representatives is no longer sufficient to meet the consultancy requirements for the complex reamers. For this reason, MAPAL is setting up its own sales organisation with technically adept and specially trained field staff. As technical advisers they offer customers solutions rather than just products.

The close co-operation between the sales, development and production departments, literally just a short distance apart, has proved to be highly advantageous. Solutions for special customer requirements are quickly developed in MAPAL's research and development department and implemented in the production of sample tools at short notice.

Consistent customer focus and a high level of flexibility and reliability in the realisation of solutions make MAPAL a sought-after expert for special solutions in high-performance fine machining. With corresponding success: between 1970 and 1989, turnover rose from 3 to 87 million German Marks and the workforce grew to 480 employees.